Process Analysis

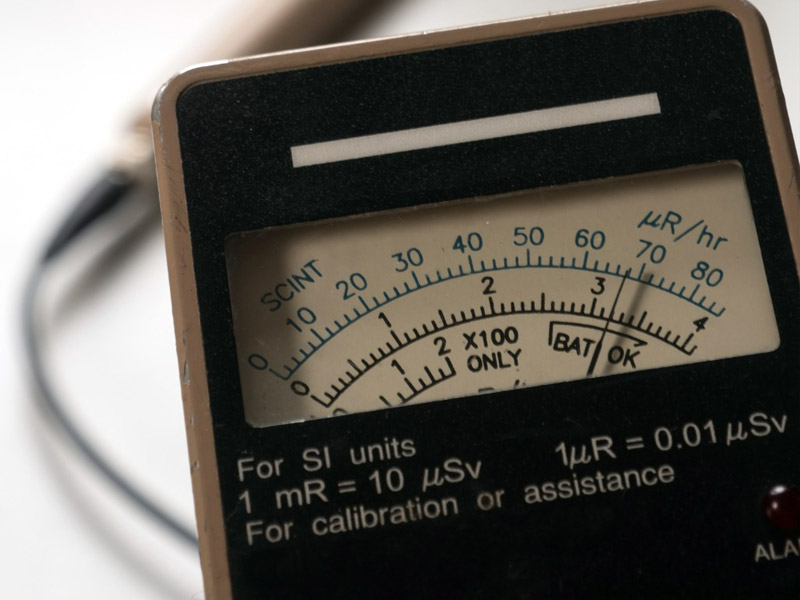

RADXION’s Process Analysis solutions center on fixed nuclear gauges that deliver continuous, non-intrusive measurement where other technologies fail. We engineer and integrate level (point & continuous), density, moisture, thickness, and mass-flow gauges for harsh process lines—high temperature, high pressure, abrasive slurries, corrosive media—without cutting, tapping, or shutting down. Our systems pair proven isotopes (e.g., Cs-137, Co-60, Am-241) with rugged detectors and smart transmitters to provide stable, drift-resistant signals with fast response and built-in diagnostics.

We handle the entire lifecycle: shielding design, licensing support, source procurement & accountability, installation/commissioning, operator training and calibration, shutter checks, leak tests, and source recycling at end-of-life. Configurations are tuned for oil & gas separators, desalters, cokers, sulfur pits, slurry lines, cement kilns, mining concentrators, and sheet/coil thickness applications—delivering actionable accuracy with minimal maintenance.

Upgrade your plant’s reliability and control with gauges that see through the process—safely, continuously, and audit-ready. Speak with our engineers to specify a fit-for-purpose package for your unit.

Nuclear Power

Industrial Manufacturer

Key Features

-

Non-intrusive, continuous measurement in extreme conditions (high temp/pressure, slurry, corrosive, foaming).

Non-intrusive, continuous measurement in extreme conditions (high temp/pressure, slurry, corrosive, foaming). -

Fast response with configurable damping for noisy processes.

Fast response with configurable damping for noisy processes. -

Level (point & continuous): separators, desalters, sulfur pits, reactors, coke drums; foam/buildup tolerant.

Level (point & continuous): separators, desalters, sulfur pits, reactors, coke drums; foam/buildup tolerant. -

Shielded source holders with positive-lock shutters; remote actuation options.

Shielded source holders with positive-lock shutters; remote actuation options. -

Moisture / Solids Content: belt/inline bulk materials (coal, cement, fertilizers, ore).

Moisture / Solids Content: belt/inline bulk materials (coal, cement, fertilizers, ore).