Disposal of X-ray Generating Analytical Machines

1. Project Overview

RADXION was contracted by a leading research institution to decommission, remove, and responsibly dispose of end-of-life X-ray analytical instruments (e.g., XRF spectrometers, XRD diffractometers, and micro-CT scanners). These devices contain regulated components—X-ray tubes, high-voltage generators, lead shielding, and electronic waste—that require specialized handling to protect personnel and the environment.

2. Objectives

-

Safe Decommissioning: Power-down, disassemble, and physically isolate all X-ray sources and high-voltage assemblies.

-

Regulatory Compliance: Ensure all radioactive-equivalent and hazardous materials are handled per IAEA SSR-6, local radiation safety, and electronic-waste regulations.

-

Environmental Stewardship: Facilitate recycling of metals and recovery of valuable components wherever feasible.

-

Full Documentation: Provide auditable records from equipment removal through final waste disposal or recycling.

3. Scope of Work

-

Pre-Decommission Survey

-

Identify all devices and map their locations.

-

Verify operational status and any residual activation or contamination.

-

-

Device Decommissioning & Disassembly

-

Disconnect power, bleed high-voltage capacitors, and lock-out/tag-out electrical circuits.

-

Remove X-ray tubes and cushion in lead-lined transport cases.

-

Dismantle internal lead shielding panels and transport to licensed radiological recycling facility.

-

Segregate circuit boards, cables, and non-shielded metal frames for e-waste recycling.

-

-

Packaging & Conditioning of Hazardous Components

-

Encapsulate X-ray tubes in Type A packaging with shock-absorbent inserts.

-

Bag and box lead shielding elements with hazardous-waste labeling.

-

Collect high-voltage capacitors and any mercury-containing switches as universal hazardous waste.

-

-

Regulatory Approvals & Transport

-

Prepare waste manifest and transport documentation compliant with ADR/RID and local environmental authority.

-

Coordinate with FANR (if any sealed sources or activation products are present) for transport licenses.

-

Engage a licensed carrier for both radioactive-equivalent and electronic hazardous components.

-

4. Equipment & Materials

-

Transport Containers: Lead-lined X-ray tube cases; UN-approved drums for capacitors and mercury devices.

-

Handling Tools: Remote grippers for hot components, torque-limited tools, and shielded transfer trolleys.

-

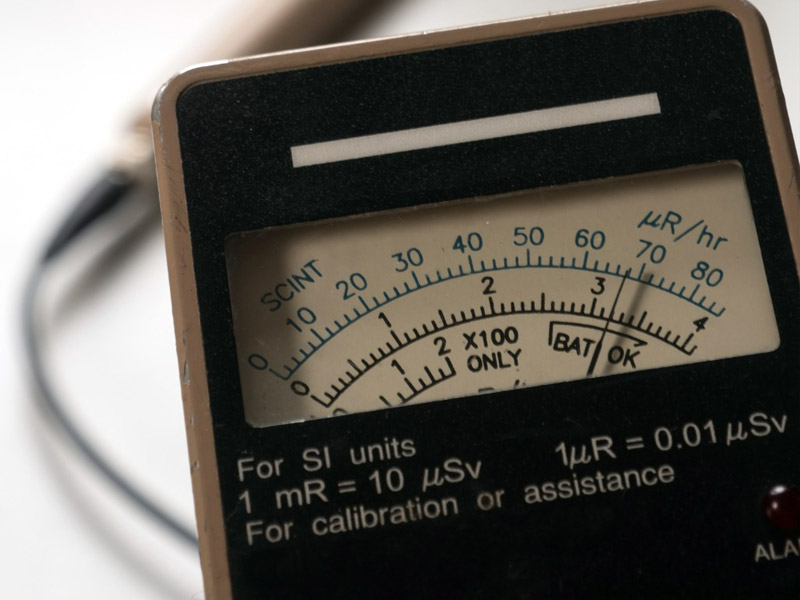

Monitoring Instruments: Portable survey meters (for any residual X-ray leakage), high-voltage tester, and contamination swipe kits.

5. Regulatory & Safety Compliance

-

Radiation Safety: IAEA SSR-6 guidelines applied to disused X-ray tubes considered “radiation sources.”

-

Electrical Safety: Lock-out/tag-out per IEC 60364 and local electrical codes.

-

Hazardous Waste: Hazardous chemical and e-waste regulations for capacitors, PCBs, and mercury switches.

-

Transport: ADR/RID for road transport; FANR licensing if any sealed-source equivalency is identified.

6. Deliverables

-

Decommissioning Report: Site atlas of all devices, residual survey results, and disassembly records.

-

Waste Manifest & Certificates: Signed hazardous-waste manifests, transport permits, and disposal/recycling certificates.

-

Recycling & Recovery Summary: Quantities of metals recycled, lead shielding forwarded, and e-waste processed.

-

Project Close-Out Document: Comprehensive record of all steps, regulatory approvals, and “lessons learned” for future device lifecycle management.