1. Project Overview

RADXION was engaged to design and deliver a permanent, purpose-built Non-Destructive Testing (NDT) bunker for industrial gamma radiography. The facility is intended for continuous, high-throughput inspection operations, ensuring maximal shielding performance, ergonomic workflow, and full regulatory compliance.

2. Objectives

-

Deliver a robust, long-term facility with minimal maintenance.

-

Provide shielding to reduce external dose rates to ≤ 0.02 mSv/h under worst-case source operations.

-

Integrate ergonomic features to streamline radiographer movements and equipment handling.

-

Incorporate advanced safety, monitoring, and emergency-response systems.

3. Scope of Work

-

Site analysis and geotechnical survey for foundation design.

-

Detailed architectural and structural engineering.

-

Shielding calculations for multiple radionuclide sources (up to Co-60).

-

Full mechanical, electrical, and control systems design.

-

Factory fabrication of modular shielding panels and on-site assembly.

-

Commissioning, acceptance testing, and staff training.

4. Site & Structural Design

-

Foundation: Reinforced concrete slab on compacted aggregate base, designed for local soil conditions.

-

Walls & Roof: 0.8 m thick reinforced concrete (density ≥ 2.5 g/cm³), with integrated steel rebar and external waterproofing membrane.

-

Flooring: Wear-resistant epoxy finish, chemical- and radiation-tolerant.

-

Access Points: Lead-lined personnel door with labyrinth seal, and a motorized load-door for equipment transfer.

5. Shielding Engineering

-

Primary Barrier: Minimum 0.8 m concrete equivalent (≥ 10⁷ attenuation at 1.25 MeV).

-

Secondary Barrier: 20 mm lead-equivalent removable panels for maintenance access.

-

Penetration Design: Custom labyrinth chases for cables and utilities; no direct line‐of‐sight paths.

-

Dose-Rate Compliance: Modeled and validated so that under continuous Co-60 operation (3.7 TBq), external dose rates remain ≤ 0.02 mSv/h.

6. Mechanical & HVAC Systems

-

Ventilation: 10 air-changes per hour via HEPA-filtered supply and exhaust.

-

Temperature Control: HVAC unit maintaining 18–24 °C for optimal equipment and operator comfort.

-

Heat Removal: Dedicated fan-coil unit on source storage alcove to dissipate decay heat.

7. Electrical & Control Systems

-

Power Distribution: Redundant feeds with UPS backup for critical loads (interlocks, alarms, lighting).

-

Interlock Logic: PLC-based control interlock, with force-off on door-open or over-temperature.

-

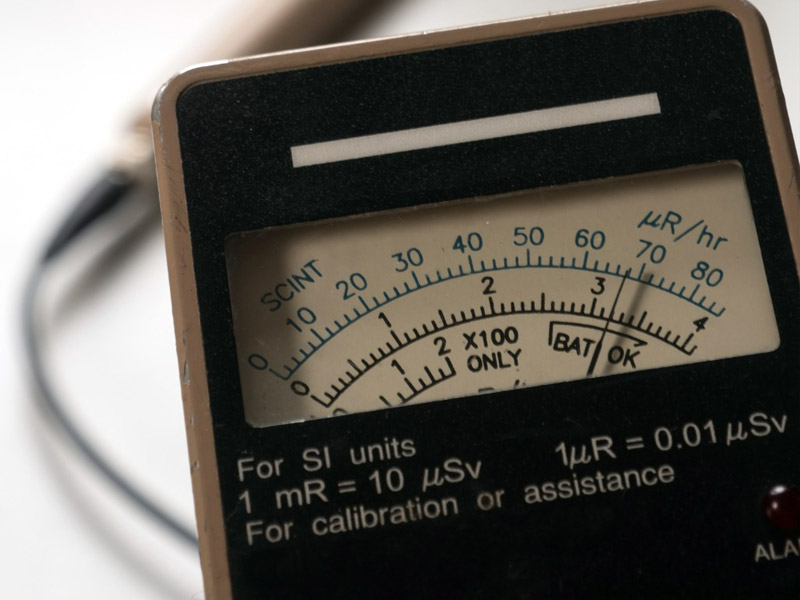

Monitoring: Networked radiation monitors (gamma and neutron), differential pressure sensors, and environmental logging.

-

Human-Machine Interface: Touchscreen panel at entry vestibule; remote monitoring console in control room.

8. Ergonomics & Workflow

-

Source Alcove: Reference-positioned cassette port with adjustable fixture height.

-

Equipment Storage: Integrated shielded lockers for sources, film cassettes, and tools.

-

Operator Path: Clearly delineated safe pathways marked with photoluminescent tape.

-

Control Room: Glass-reinforced polycarbonate viewing window with shutter and audio intercom.

9. Safety & Emergency Provisions

-

Alarms & Indicators: Visual warning strobes and sirens interlocked to source drive.

-

Fire Protection: Inert-gas fire-suppression system in source storage alcove.

-

Emergency Egress: Two means of exit; illuminated exit signs on battery backup.

-

Drills & Procedures: Provision of emergency-response plan and annual full evacuation drills.

10. Materials & Procurement

-

Concrete: High-density mix with iron-oxide aggregate (≥ 2.5 g/cm³).

-

Shielding Panels: Factory-cast lead modules in stainless-steel trays.

-

Structural Steel: S355 marine-grade for door frames and support lintels.

-

Finishes & Sealants: Radiation-tolerant epoxy coatings; silicone gaskets rated for –40 °C to +150 °C.

11. Regulatory Compliance

-

IAEA SSR-6 for Category I sources and Type B(U) packages.

-

Local building code approvals for industrial radiation facilities.

-

ISO 11625 interlock and alarm performance standards.

-

FANR (UAE) licensing for fixed radiographic installations.

12. Deliverables & Timeline

-

Design Package: Civil, mechanical, electrical drawings and shielding report (Month 1–3).

-

Fabrication & Delivery: Shielding modules and mechanical skids (Month 4–6).

-

Site Works & Assembly: Civil works and installation (Month 7–9).

-

Commissioning & Handover: Acceptance testing, documentation, and training (Month 10).

13. Conclusion

RADXION’s permanent NDT bunker design delivers a high-performance, future-proof facility that maximizes operator safety, regulatory compliance, and operational efficiency for all routine and high-throughput industrial radiography tasks.