Mobile Onshore Radioactive Material Storage

1. Introduction

This project covers the design and fabrication of a self-contained, towable onshore unit for interim storage of radioactive materials. The unit is optimized for rapid deployment to construction sites, temporary facilities, and remote work areas, ensuring safe handling until permanent disposal or long-term storage is available.

2. Objectives

-

Mobility: Permit road transport via standard heavy-duty trailers.

-

Safety: Provide multi-layer radiation shielding, secondary containment, and active cooling.

-

Compliance: Conform to IAEA Type B package requirements and national land-transport regulations.

3. Scope

-

Conceptual and detailed engineering design

-

Fabrication of modular shielded modules and support chassis

-

Integration of cooling, containment, and monitoring subsystems

-

Factory acceptance testing and on-site commissioning

4. Design Features

-

Shielded Storage Modules: Cylindrical stainless-steel liners encased in lead and high-density concrete.

-

Chassis & Enclosure: Reinforced steel frame on a 20 ft flat-bed trailer, with weather-proof steel canopy.

-

Secondary Containment: Fully sealed inner vault with leak-detection sensors.

-

Active Thermal Control: Air-cooled heat exchangers and thermostatically-controlled fans.

-

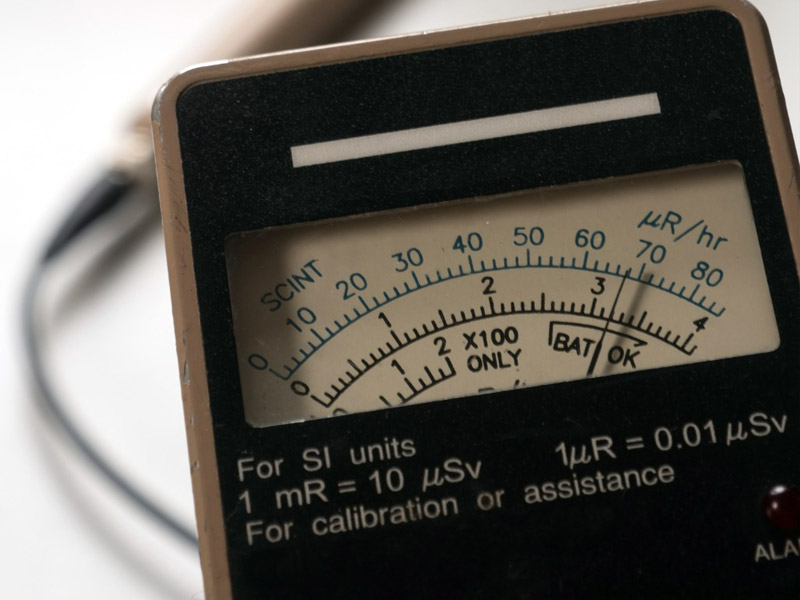

Monitoring & Control: Embedded gamma sensors, temperature probes, and remote telemetry link.

5. Fabrication Details

-

Module Manufacture

-

Precision-machining of stainless-steel liners.

-

Layered casting of lead shielding; pour and cure of high-density concrete.

-

Weld seams to Class 1 radiographic quality standards.

-

-

Chassis Assembly

-

Installation of reinforced subframe on heavy-duty trailer.

-

Mounting of shielded modules into precision-aligned cradles.

-

Construction of steel canopy with integrated access hatches and lift points.

-

-

Systems Integration

-

Plumbing of cooling air ducts and installation of fan-driven heat exchangers.

-

Wiring of power, control, and telemetry harnesses into sealed junction boxes.

-

Calibration of sensors; perform pressure- and leak-tests on containment barriers.

-

6. Safety & Redundancy

-

Primary Shielding: Minimum 0.4 m lead equivalent around all module surfaces.

-

Backup Cooling: Dual-fan arrangement with automatic fail-over.

-

Emergency Response: Automated unit lockdown and alarm on threshold exceedance; remote isolation of power and ventilation.

7. Materials & Procurement

-

Shielding Components: Lead alloy ingots; high-density concrete mix (> 5.5 g/cm³).

-

Structural Elements: A514 marine-grade steel for frame and canopy.

-

Ancillaries: Radiation-resistant seals, road-legal lighting and signage, heavy-duty lifting eyebolts.

8. Deployment & Transportation

-

Compatible with C-Class commercial highways under special-load permit.

-

Trailer hitch and hydraulic leveling jacks for rapid site setup.

-

Designed for 80 km/h transport; road vibration dampening via shock-mounts.

9. Site Integration

-

Flat, leveled pad required (e.g., compacted gravel or concrete slab).

-

Forklift pockets and integrated crane-lift points for off-trailer placement.

-

Optional modular ramp for direct access to module hatches.

10. Regulatory Compliance

-

IAEA SSR-6 and ADR/RID land-transport standards.

-

ISO 11625 Type B(U) package certification.

-

Local transport authority approval for oversize/overweight loads.