Mobile Offshore Radioactive Material Storage

1. Introduction

This project centers on the design and fabrication of a self-contained, towable storage system for radioactive materials, optimized for offshore deployment. It ensures safe, compliant, and flexible interim storage near offshore facilities (e.g., oil platforms, wind farms).

2. Objectives

Mobility: Enable rapid repositioning by tug or support vessel.

Safety: Provide multi-layer shielding, containment, and active cooling.

Compliance: Meet IAEA Type B package standards and local maritime regulations.

3. Scope

Conceptual and detailed design

Fabrication of modular storage casks and barge structure

Integration of shielding, cooling, and monitoring systems

Sea-trial testing and certification

4. Design Features

Modular Casks: Heavy-wall stainless steel with lead/concrete layers.

Shielding Walls: Surround casks on three sides, integrated into the barge deck.

Containment Barrier: Secondary sealed enclosure with leak-detection sensors.

Active Cooling: Air- or seawater-based heat exchangers to dissipate decay heat.

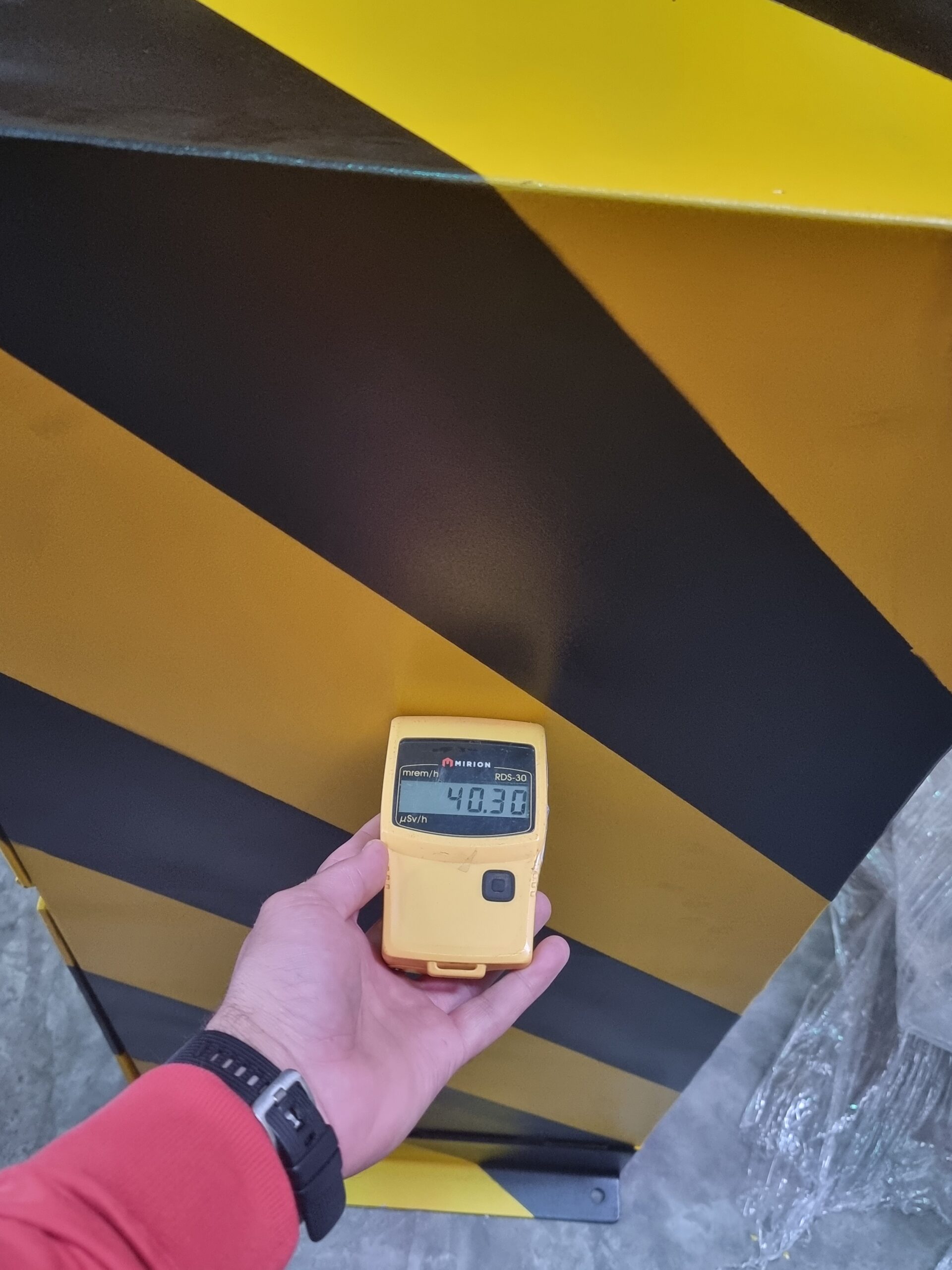

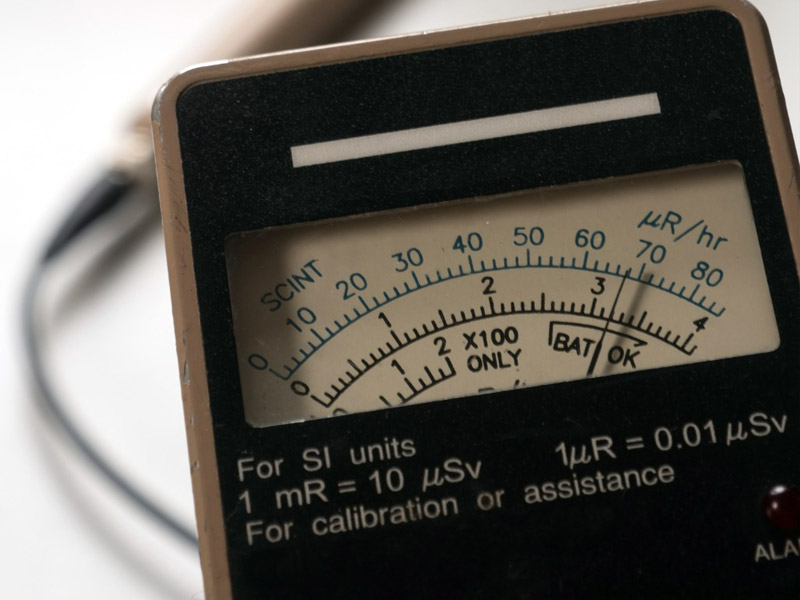

Monitoring & Controls: Real-time radiation detectors, temperature sensors, and remote telemetry.

5. Fabrication Details

Module Preparation

Machine inner stainless-steel liners.

Cast concentric lead shielding and pour high-density concrete.

Seal casks to Class 1 weld standards.

Structural Assembly

Retrofit a 30 m × 10 m barge with reinforced deck plates.

Weld vertical shielding panels; install containment canopy.

Mount cooling skid and electrical/mechanical control cabin.

Final Integration

Bolt casks to deck mounts; connect cooling loops and power.

Calibrate monitoring systems; perform hydrostatic and radiological tests.

6. Safety & Redundancy

Primary Shielding: ≥ 0.5 m lead equivalent on all sides.

Backup Systems: Dual-pump cooling, redundant power supplies.

Emergency Protocols: Automated safe-shutdown on sensor trip; remote-controlled isolation valves.

7. Materials & Procurement

Shielding: Lead alloys, high-density concrete (> 5.6 g/cm³).

Structure: Marine-grade steel (A36 or equivalent).

Ancillaries: Seismic-qualified containment seals, marine-rated piping.

8. Deployment & Transportation

Towable via standard offshore support tugs.

Mooring fittings for single-point or spread-mooring systems.

Capable of 5 knots transit in up to Sea State 4 conditions.

9. Offshore Integration

Designed to interface with platform cranes or gangways.

Compatible with dynamic positioning vessels for precise station-keeping.

10. Regulatory Compliance

IAEA SSR-6 and IMDG Code for maritime transport.

Lloyd’s Register certification for offshore structures.

UAE FANR Type B package approval process.