Project Context & Operational Environment

Managing and storing sealed radioactive sources offshore—whether aboard platform modules, support vessels, or FPSOs—poses unique challenges: limited space, motion-induced stresses, marine corrosion, and stringent maritime and radiation‐safety regulations. RadXion’s assessment covers both temporary at‐sea storage (e.g., during drilling campaigns) and permanent on‐platform source banks (e.g., for well-logging sources).

Regulatory Framework & Licensing Requirements

-

Maritime & Nuclear Authorities

-

Coordinate with flag‐state maritime regulators (e.g., the UAE’s Maritime Sector, IMO guidelines) and national nuclear/radiation bodies (FANR, K.A.CARE) to ascertain overlapping requirements.

-

-

Application Dossier

-

Source inventory: activities, encapsulation type (e.g., Am-241, Cs-137 in stainless steel capsules)

-

Offshore facility drawings: designated source-storage rooms, access routes, confinement barriers

-

Environmental Impact Assessment (EIA) addendum addressing potential sea‐water exposure and spill scenarios

-

-

Authorization Process

-

Submit “Authorization to Install” for permanent on‐platform vaults and “Authorization to Transport and Store” for temporary sea‐borne storage units.

-

Liaise with Port State Control and Civil Defence Marine Protection units for joint inspections.

-

Storage-Vault & Shielding Design

-

Vault Structural Integrity

-

Design a dedicated stainless‐steel lined vault, welded to the deck support structure, capable of withstanding platform motions, salt spray, and fire loads.

-

-

Shielding Calculations

-

Use point‐source and line‐source build‐up factors per NCRP‐151 to size lead or tungsten alloy panels, ensuring external dose‐rates ≤ 0.02 mSv/h in adjacent work and escape‐route zones.

-

Account for multi‐directional exposure due to ship heave and roll by modeling worst‐case orientations in Monte Carlo tools (e.g., Geant4).

-

Environmental & Structural Risk Assessment

-

Corrosion & Seawater Interaction

-

Specify marine‐grade coatings (e.g., 316L stainless backup) and desiccant systems to prevent container seal degradation.

-

-

Motion and Vibration

-

Perform FEA on storage racks to verify that accelerations up to 0.5 g in all axes do not compromise source capsules or shielding assemblies.

-

-

Fire & Flood Scenarios

-

Integrate the vault into the platform’s fire‐rated compartments and confirm watertight integrity against 1 m inundation for at least 2 hours.

-

Instrumentation & Monitoring Systems

-

Fixed Radiation Monitors

-

Install gamma‐rate detectors on bulkhead walls adjacent to the vault, calibrated for offshore temperature and humidity ranges, linked into the platform’s safety PLC.

-

-

Continuous Environmental Sampling

-

Equip vault ventilation exhaust (if used) with particulate filters and real‐time gamma spectrometry to detect capsule breach events.

-

-

Remote Data Logging

-

Route all dose‐rate and environmental sensor data to the platform’s Distributed Control System (DCS) with alarm thresholds for automatic source lockdown.

-

Access Control & Interlock Integration

-

Mechanical Interlocks

-

Vault door equipped with two‐factor locks (engineer key + access code), interlocked with radiation detectors so that opening is inhibited if dose‐rate > 0.1 µSv/h inside.

-

-

Procedural Safeguards

-

Restricted access permits, time‐limited authorization cards, and mandatory two‐person rule for any source movement.

-

Personnel Protection & Emergency Preparedness

-

Marine-Specific PPE

-

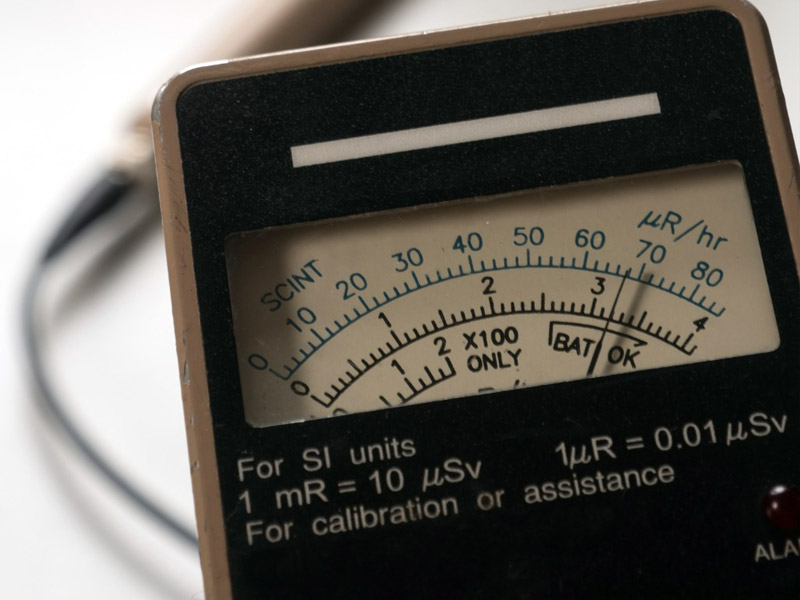

Corrosion‐resistant, anti‐slip footwear and offshore‐rated coveralls; portable radiation meters rated for marine environments.

-

-

Drills & Contingencies

-

Simulated “source‐drop” and “water ingress” drills integrated into platform emergency response exercises, coordinating with the platform’s muster‐station protocols.

-

Commissioning, Survey & Validation

-

Mechanical & Radiological Acceptance

-

Structural sign-off by marine engineers; leak‐test and wipe‐test of each source capsule; full deck-level dose‐mapping under static and dynamic (simulated roll) conditions.

-

-

Performance Verification

-

Demonstrate via time-lapse logging that vault dose‐rates remain stable within design margins over a 72-hour sea‐state simulation.

-

Outcomes & Operational Benefits

-

Certified Offshore Storage

-

Regulatory “Safe to Operate” certificate granted on first inspection, enabling uninterrupted drilling/logging schedules.

-

-

Robust Marine Performance

-

Vault design exceeded corrosion and vibration criteria, reducing maintenance intervals by 30 %.

-

-

Enhanced Safety & Compliance

-

Dose‐rates in adjacent living quarters and escape routes measured < 0.005 mSv/h; no contamination events recorded in first 12 months.

-

-

Integrated Monitoring

-

Real-time telemetry ensures remote shore-based oversight and rapid response to any alarm conditions.

-

By harmonizing maritime engineering, advanced shielding analytics, and stringent radiation‐safety protocols, RadXion delivers turnkey offshore source-storage solutions that comply with all GCC marine and nuclear regulations while safeguarding personnel, assets, and the environment.