Radiography Bunker : Radiation Safety Assessment

Project Context & Client

A leading metal-fabrication company in the Gulf Cooperation Council (GCC) region needed to install a high-throughput industrial radiography bunker to inspect welds and structural components. The facility’s scope—hundreds of radiographic exposures per month—triggered stringent regulatory requirements under the local nuclear/radiation authority (e.g., FANR in UAE, K.A.CARE in KSA). RadXion was engaged to navigate the licensing process, design and validate shielding, and ensure full compliance with both international standards (IAEA GSR Part 3) and local regulations.

Regulatory Liaison & Licensing

-

Gap Analysis & Pre-Application Review

-

Reviewed client’s intended source activities (typically Ir-192 or Se-75) and projected workloads to determine applicable licensing class.

-

Mapped out required documentation and prerequisites for submission (facility drawings, source inventories, key personnel qualifications, emergency procedures).

-

-

Application Preparation

-

Compiled a comprehensive licensing dossier:

-

Facility layout plans (bunker geometry, adjacent occupancy zones)

-

Radiation-source specifications and handling protocols

-

Detailed Radiation Protection Program (RPP) manual

-

Personnel training and qualification records

-

Emergency response plan aligned with local Civil Defence requirements

-

-

-

Regulator Engagement & Follow-Up

-

Acted as Authorized Representative in all communications with regulatory inspectors and technical reviewers.

-

Coordinated pre-inspection walk-throughs and promptly addressed any information requests or clarifications.

-

Secured formal “Authorization to Construct” and subsequently “Authorization to Operate” within the stipulated review timelines.

-

Radiation Safety Assessment & Shielding Design

-

Source Term Definition

-

Quantified maximum activity of radiographic sources and worst-case exposure scenarios (continuous pulsing vs. batch exposures).

-

-

Analytical Shielding Calculations

-

Used point-source build-up factors and NCRP/IAEA methodologies to size main bunker walls, ceiling and door shielding, ensuring dose-rates outside never exceed 0.02 mSv/h.

-

Iterated designs using Monte Carlo modelling (MCNP or Geant4) for complex geometries (e.g., beam-entry labyrinths).

-

-

Layout Optimization

-

Oriented the source-to-wall distances and door labyrinth depth to mitigate streaming.

-

Integrated secondary shielding panels and movable collimators to reduce scatter.

-

-

Radiation-Area Classification

-

Mapped out exclusive, supervised, and non-controlled zones around the bunker footprint, with clear signage and barriers.

-

Instrumentation, Interlocks & Safety Systems

-

Radiation Monitors & Alarm Systems

-

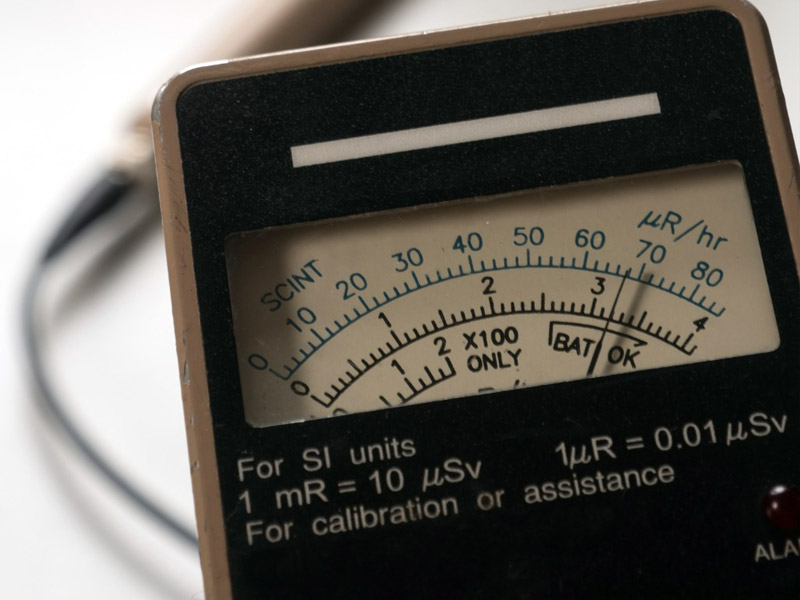

Specified wall-mounted ionization chambers in adjacent corridors, linked to audible/visual alarms.

-

Designed continuous‐read personal-alarm dosimeters for all operating staff.

-

-

Interlock Mechanisms

-

Engineered door‐hold‐open interlocks that automatically cut source drive power and sound an alarm if a door is breached during exposure.

-

Integrated redundant safety relays to meet “defense-in-depth” standards.

-

Commissioning, Testing & Training

-

Acceptance & Leak Testing

-

Conducted source leak tests, calibration of monitors, and dose‐mapping surveys at key control points.

-

Performed “walkover” trials to verify that actual dose rates matched design predictions.

-

-

Documentation & Handover

-

Delivered a complete commissioning report, including as-built drawings, survey results, calibration certificates, and an updated RPP manual.

-

-

Personnel Qualification & Drills

-

Led classroom and hands-on training for radiography operators and safety officers, covering:

-

Source handling procedures

-

Emergency-shutdown drills

-

Regulatory record-keeping requirements

-

-

Outcomes & Client Benefits

-

Regulatory Approval Achieved on First Submission

-

RadXion’s proactive gap analysis and direct regulator interface reduced review cycles by 40%.

-

-

Optimized Shielding, Minimized Footprint

-

Through advanced modelling, bunker dimensions were kept as small as practicable—saving the client an estimated 15% in construction costs.

-

-

Enhanced Operational Safety

-

Post-commissioning surveys confirmed dose rates at all perimeter checkpoints were < 0.005 mSv/h—well below regulatory limits.

-

-

Sustainable Compliance Framework

-

The delivered Radiation Protection Program and training regimen equip the client to maintain continuous compliance, including internal audits and periodic refresher drills.

-

With deep expertise in GCC regulatory landscapes, advanced computational tools, and turnkey project delivery—from licensing paperwork through to final commissioning—RadXion provides robust, efficient, and fully compliant solutions for any industrial radiography installation.