1. Project Overview

RADXION was commissioned to design and deliver a turnkey radiation-shielding solution for a new research laboratory housing a 150 kV X-ray diffraction system and a Cs-137 irradiator. The work encompassed conceptual engineering, detailed shielding calculations, fabrication drawings, and on-site integration of bulk shielding, penetration chases, and access controls.

2. Objectives

-

Dose-Rate Control: Ensure external dose rates in adjoining offices and public corridors remain ≤ 0.02 mSv/h under maximum operating conditions.

-

Ergonomic Access: Integrate service panels and labyrinth entrance to facilitate routine maintenance without compromising shielding integrity.

-

Regulatory Compliance: Meet IAEA SSR-6, local radiation protection regulations, and building-code requirements for structural loads.

-

Future-Proofing: Allow for accommodation of a potential upgrade to a 300 kV X-ray source with minimal modifications.

3. Scope of Work

-

Shielding Assessment & Calculations

-

Compute required barrier thicknesses for 150 kV X-rays (broad-beam geometry) and 662 keV gammas using point-kernel methods.

-

Model scatter contributions to control‐room interior using Monte Carlo verification.

-

-

Architectural & Structural Integration

-

Develop CAD drawings for 0.4 m–0.6 m thick high-density concrete walls (ρ ≥ 3.2 g/cm³).

-

Specify reinforced steel lintels for door and window penetrations.

-

-

Penetrations & Labyrinth Design

-

Design cable and duct chases with double-offset dog-leg geometry to prevent streaming.

-

Detail a double-door labyrinth entry, including interlocked doors and warning lights.

-

-

Shielded Viewing Window & Equipment Ports

-

Specify 50 mm lead-equivalent polycarbonate window with laminated safety glass backing.

-

Design shielded feed-through ports for power, data, and utilities with removable lead collars.

-

4. Design Considerations

-

Beam Geometry: Account for primary, scatter, and leakage radiation paths.

-

Occupancy Factors: Evaluate adjacent spaces for “controlled” vs. “supervised” occupancy classifications.

-

Structural Loads: Verify that additional concrete density does not exceed slab loading limits.

-

Serviceability: Include removable access panels for source replacement and wall-chasing.

5. Materials & Construction

-

High-Density Concrete: Iron-oxide–enhanced mix achieving 3.2 g/cm³, cast in-place.

-

Lead Sheet Lining: 10 mm Pb sheets behind wall finishes in high-flux zones.

-

Steel Framing: S355 structural steel for door frames and lintels.

-

Sealants & Gaskets: Radiation-resistant silicone for panel joints; labyrinth door seals rated to –40 °C to +120 °C.

6. Safety Features & Compliance

-

Interlocks: PLC-controlled door interlocks with fail-safe relays on source drives.

-

Warning Systems: Exterior warning lights, audible alarms, and beacon chain tied into building fire system.

-

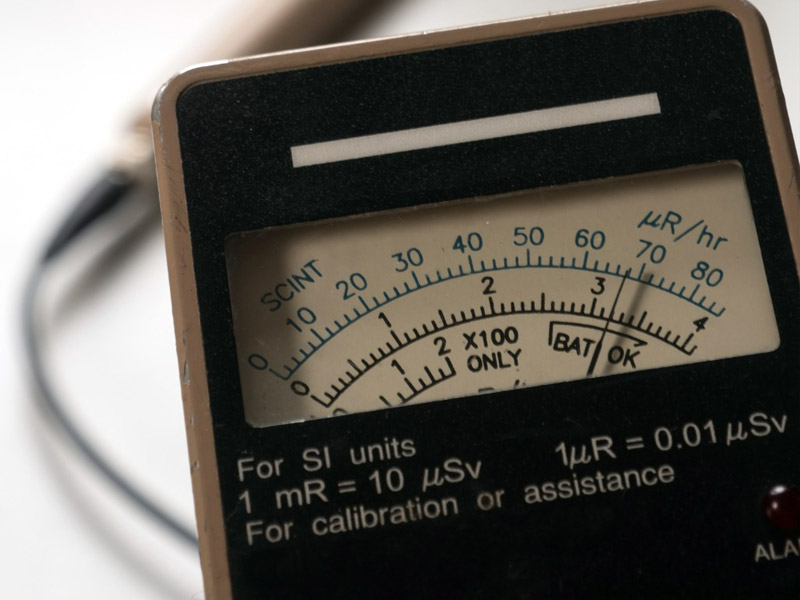

Survey Ports: Embedded labyrinth‐sealed survey tubes for easy quarterly dose checks.

-

Documentation: Comprehensive shielding report, “as-built” drawings, and regulatory submission package for FANR approval.

7. Deliverables

-

Shielding Calculation Report (including Monte Carlo validation plots).

-

Fabrication & Installation Drawings for walls, doors, windows, and chases.

-

Material Specification Sheet for concrete mix, lead lining, and sealants.

-

Compliance Package with IAEA SSR-6 justification, local permit applications, and safety datasheets.

-

Post-Installation Verification: On-site radiation surveys and “Certificate of Compliance” for operational handover.