| Subsector |

RPO Track Modules |

Technician Track Modules |

| Radiographic Testing (RT) |

- Fundamentals of radiation physics & interaction (γ, X-rays)

- National & international RT regulations (IAEA, local)

- RT facility design & shielding calculations

- Quality assurance, dose auditing & record-keeping

- Audit & inspection protocols

- Emergency planning & incident investigation

|

- Basics of radiation physics

- RT equipment operation & calibration

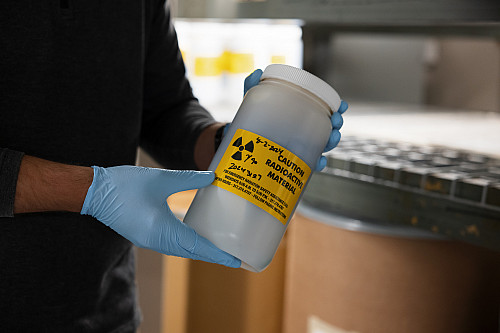

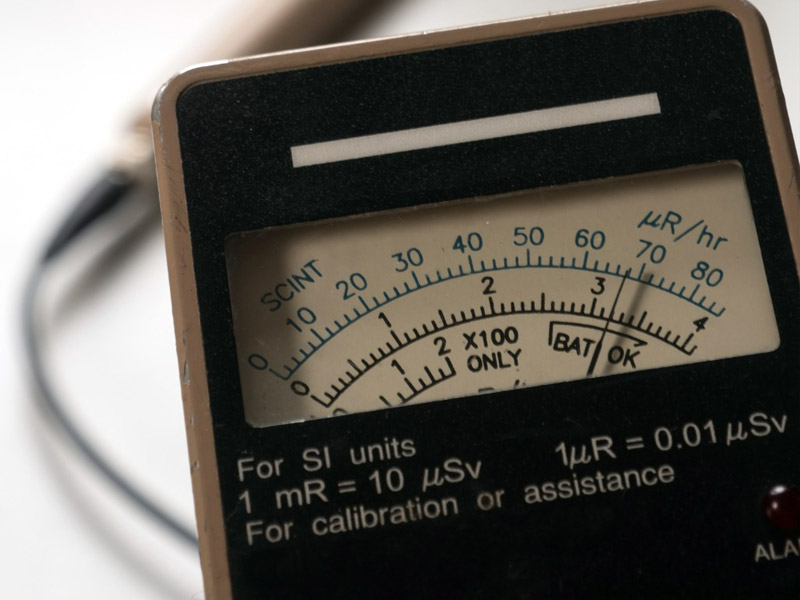

- Radiation survey techniques & instrumentation

- Personal monitoring (TLD, electronic dosimeters)

- Source handling, transport & transfer procedures

- Contamination control & decontamination

|

| Industrial Gauging & Level/Density Measurement |

- Gauge-specific regulations & licensing

- Shielding design for sealed sources

- Performance testing & acceptance criteria

- QA/QC for gauge installation & periodic inspection

- Record-keeping & regulatory reporting

|

- Gauge installation, alignment & start-up

- Daily/weekly radiation surveys & leak tests

- Source exchange procedures

- Hands-on instrumentation (GM, ion chambers)

- Maintenance, troubleshooting & emergency shut-down

|

| Well Logging (Oil & Gas) |

- Well-logging source types & licensing (Ir-192, Cs-137)

- Transport packaging, shipment documentation

- Regulatory oversight of down-hole operations

- Audit procedures & dose audit for crews

|

- Borehole tool assembly & source loading

- Down-hole measurement protocols

- Real-time dose monitoring & record-keeping

- Source recovery & emergency procedures

|

| Industrial Irradiators & Sterilization Units |

- Facility design, maze calculations & access controls

- Process validation & QA programs

- Calibration of dose-mapping instruments

- Regulatory compliance (food, medical device irradiation)

|

- Irradiator start/stop procedures

- Product mapping & dose-mapping surveys

- Instrument calibration & routine checks

- Emergency procedures (source return, area evacuation)

|